Instron Die Set Testing, Membrane Cutting, and Report

This project originated from observed issues on the manufacturing line at MilliporeSigma’s Cork, Ireland facility, where variations in membrane cutting performance were affecting product consistency. To address this, I designed and built a custom fixture for the Instron testing machine to measure the force required to cut membranes using different punches and dies. The goal was to quantify drag forces, identify optimal tolerances, and establish a standardized cutting process. I modeled the parts and assemblies in SolidWorks, created detailed machining drawings, selected and procured hardware, and assembled the final test setup. I then conducted testing, analyzed the data, and compiled a comprehensive report outlining findings and recommendations for process improvement.

I first started by getting an off-the shelf die set, made modifications to it in CAD, and created other necessary fixture parts, drafted detailed drawings for off-site machine shop.

Image 1: CAD Assembly of off-the shelf die set with modifications

Image 2: Modified Top Die Set Plate Drawing

Image 3: Modified Bottom Diet Set Plate Drawing

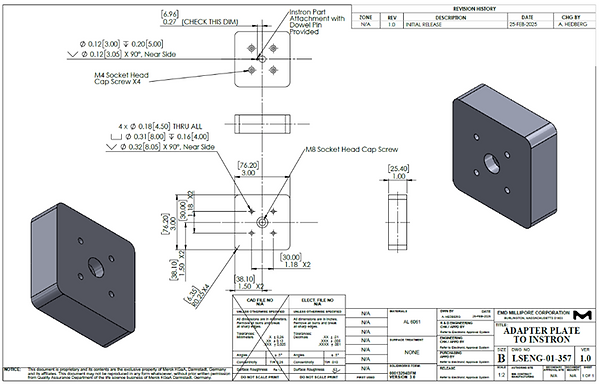

Image 4: Adapter Platte from Top Die Set Plate to Instron Machine

Images 5 and 6: In-lab Instron Setup on left and image on right is of Instron Bluehill Data Software

Images 7 and 8: Displaying data from testing

Image 9: Images of pages from full report and key findings